Sooner or later I had to tackle the big problem in home casting…the Kiln. I don’t know why I was so afraid of this step, perhaps it had something to do with the idea of building a box that can easily get up to 1200 C (Over 2100 f), or the electrical work, or the unfamiliarity of the whole project. But in retrospect it was super easy, and I have the internet to thank for that.

I am deeply indebted to a number of online sources for the knowledge I gleaned in how to make this kiln (I will list them all at the end), but first and foremost this instructable by Sure Hacksalot was my bible, my savior, and more importantly my safety blanket that calmed my worries. I honestly can not thank this person enough as he has made it possible for me to build myself a kiln that does everything I want for a small fraction of the cost of a commercial model.

These are not step by step instructions, for that see Sure Hacksalot’s instructable, as he has done a much better job than I ever could in laying out the steps.

If you are like me, the idea of building your own kiln is a bit daunting, I mean the damn thing is going to get really really really hot, and there are electronics, and electricity, and did I mention the really hot…yea, but in essence what you are doing is building a tiny box, and keeping all the heat inside it. It’s not very hard, no really, its pretty easy. Screw your courage to the sticking place and charge forth!

I put in links to where I purchased some of this stuff, you can get it many places though

You will need the following:

a length of Kanthal A1 resistance wire (I used 25 feet of 16g for my element, this wire is used because it can achieve the high temps needed) Buy

some K23 refractory fire bricks (I used two different shapes) Buy here and here.

Some threaded rod, and angle iron (got at home depot)

Some nuts, bolts and washers (had laying around)

A PID temp controller (I used the AGPTek Dual Digital SSR) Buy

A K Type thermocouple rated for at least 1200C (Make sure to get one with a long enough probe to fit through your fire brick) buy

A 25A rated solid state relay (be sure to get AC not DC) Buy

Some hefty gauge wire (had some laying around)

Tools needed:

a Philips head screwdriver

a hand saw (not a power saw)

a Dremel tool with the router head and bits (not technically needed but super helpful)

a drill bit the same size as your thermocouple probe

The Heating Element:

The heating element is a type of wire that gets very hot when you run electricity through it. It uses a special kind of wire called Kanthal A1 wire. You have to “size” your element so that it draws enough electricity to heat up hot enough, but not so much you blow out the breaker.

First figure out the maximum amp rating of your breaker, mine was 15.

Next determine the voltage rating for your home mine was 120.

You can not draw more Amps than your breaker can handle, and if you want to be safe and have anything else on when you are using your kiln, its a good idea to stay well below the maximum.

To figure out how many Amps your element will use, use the following math formulas:

Amps = volts / Ohms

Watts = volts X amps

Ohms = volts /Amps

Ohms is a measure of resistance, to figure that out you need to consult a chart for Kanthal A1 wire. The resistance or Ohms is per foot, so different thickness wires, and different length wires will give you different resistance.

I used 16g wire, which has a resistance of .324 ohms per foot. Using the formula above Ohms = 120 volts/15 amps = 8. However I don’t want to peg my kiln at the max, so I am going to use 7.3. Since my 16 g wire has .324 ohms per foot I take 7.3 (my max ohms) /.324 (ohms per foot of my wire) = 22.5 feet of wire.

I measured out 22.5 feet of wire and then built a bootleg wire coil maker out of a piece of threaded rod, two nuts, a wrench, and a piece of wood (to save my fingers, this stuff is stiff). I basically secured one end of the wire between two nuts on one side of the rod, then used the nuts to attach the wrench to turn it. I used the chunk of wood to hold the wire close to the coil as I slowly turned it with the wrench. I used 1/4 inch rod, which works well.

Once you are done, uncoil the wire from the rod, it will spring open a bit, but you will still have to “unscrew” the rod from the coil, the whole process took about 10 minutes. Next you will need to stretch the coil, this is because the coils can not touch each other or they will short out. Stretch the coil by pulling on it until there is about 2 wire thickness’ between each coil. It will be significantly longer after you do this.

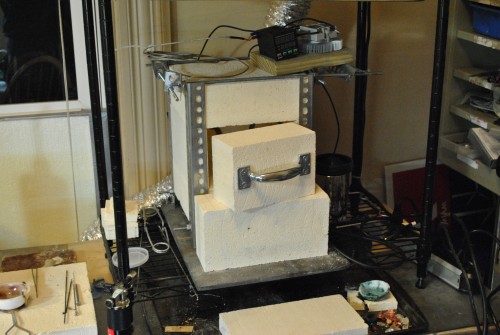

The Kiln Housing:

This is actually the easiest part of the build. You are basically playing with blocks. Some things to keep in mind. Refractory fire bricks are VERY fragile. They are very brittle and break easily. They are also very light, and easy to cut. They also produce a dust that will give you serious lung problems if you breath it, so a safety mask is a MUST for this step. Frequent clean up is good, do the cutting outside, they make a lot of dust.

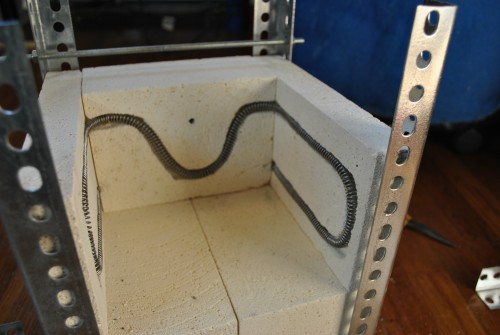

The design I came up with is a compromise between having enough space to do more than one flask at a time (see the skinny side walls), having enough space to actually fit my entire element into the kiln, and keeping the kiln small enough so that it will get hot enough.

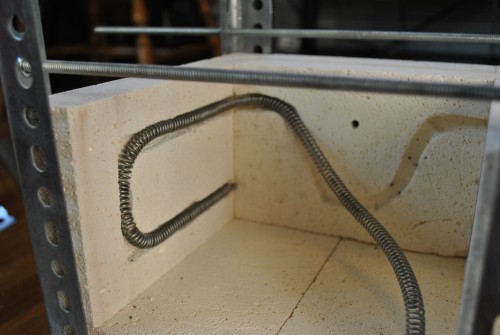

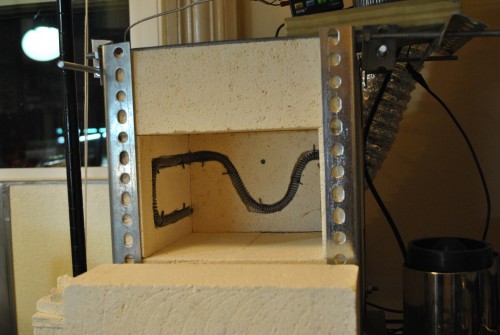

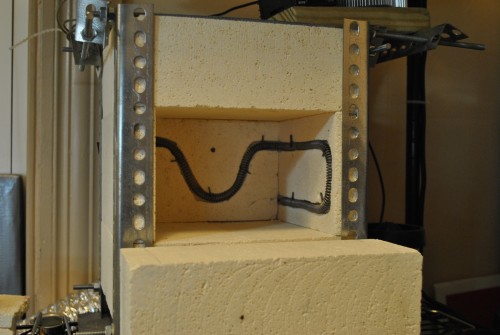

Use angle iron and threaded rods to hold the kiln together. I used a Dremel with a routing attachment to route out the channels for the element, I left two long straight sections of wire that poke out through the back (be sure they are not touching the metal frame or you will short out the system.) That small hole in the back brick is where the thermocouple will poke through. I suggest you only let a couple mm of the probe stick through to keep it from oxidizing and melting (it gets hot in the kiln!).

The threaded rod along the top here is installed temporarily, see below for the final configuration.

Once the element is placed in the kiln you will need to pin it down to keep it from moving when it heats up (hot things expand). I used stee “T” pins with the end cut off, they seem to work well.

Use more than you think you will need, the element will move a lot.

The connectors for the back, the Kanthal Wire connects to one side of the bolt, and the copper to the other, this helps to keep that connection cool. I used a big thick piece of copper wire here, because these ends of the resistance wire get very hot, so having something that can take the heat is nice. The wire leads will connect to the very end of the copper rod, which by then has cooled enough to connect the insulated wire to.

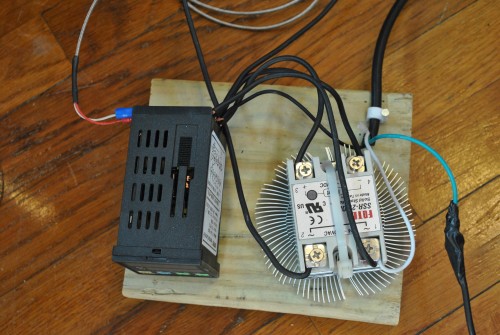

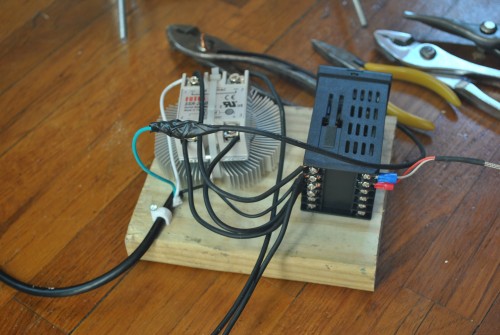

The Electronic Temperature Controller:

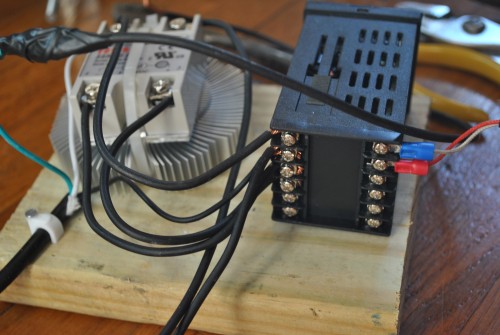

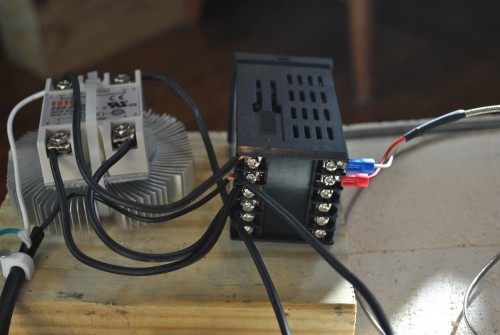

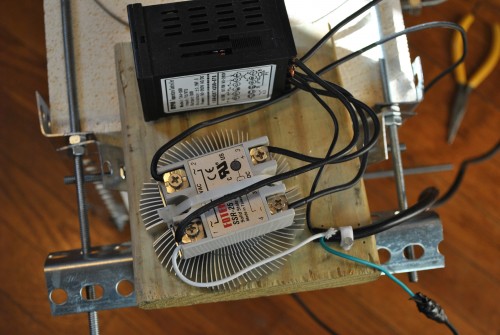

This for me was the most intimidating part. Mostly because the parts came with Chinese instruction manuals that looked like they had been written in Italian google translated into Mandarin, and then google translated into English…the internet was vital to understanding this. See the instructable linked above for a good wiring diagram, but in essence here is how it works.

A thermocouple is connected to the PID (the black box), the thermocouple tells the PID what temp it is in your kiln, the PID turns on and off the juice by using the Solid State Relay (the white thing) to keep the temp you set, the SSR is connected to a heat sink from a computer because it gets hot and the heat sink helps dissipate that heat. You will need some kind heat sink for your SSR as it gets very hot and over heating will limit its life.

The red and blue wires are from the thermocouple

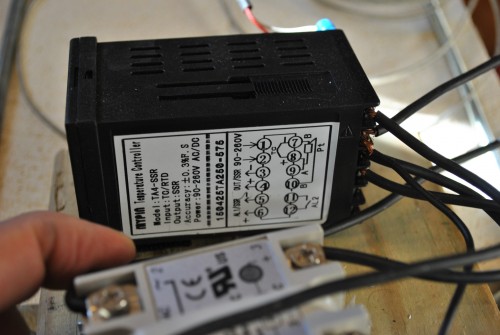

This diagram is actually vital to understand, let me see if I can translate (because the instructions that come with the PID certainly do not help)

1 and 2 are the power, this PID will accept between 90 and 280 volts

3 is the negative lead to the SSR

4 is the positive lead to the SSR

5 and 6 are for a second SSR if you want to wire up more than one element (I didn’t use this feature)

7 and 8 are the + and – for the thermocouple

9-12 i have no idea, I didn’t use these.

Your PID will most likely be different, just follow its wiring diagram and you should be fine. The ground from the cord is attached to the frame. Obviously there are exposed wires in the back of this, so don’t go grabbing them when the kiln is on. Also the elements themselves, aside from being hot also are electrified so be sure when putting things in the kiln you don’t jam a metal pair of tongs into them.

For a door I used an extra brick and cut it to size, it fits snugly in the opening and rests on a another brick. This other brick is useful for placing things you recently took out/will put into the kiln on as well.

My messy studio.

One ruined crucible and some melted brass, this baby cooks! I easily got it up to 1200c.

It took me a long time to feel ok about building this. I had to read a lot on the internet to feel comfortable enough to build it, but in the end it really wasn’t that hard. If I had to do it again I think I would feel much more comfortable about the whole process.

Safety:

You will need high temp gloves, like welding gloves, the kiln gets so hot you literally can’t get your hand near it. I also suggest a full face mask, or at the least eye protection. You will also need a leather or heavy canvas apron, wear closed toe shoes, and have good ventilation.

Resources:

Start Here:

http://www.instructables.com/id/Casting-Rings-From-Startup-to-Finish/

http://www.ganoksin.com/orchid/archive/201501/msg00035.htm

General Casting Tips:

http://www.instructables.com/id/Lost-Wax-Casting/

Kanthal A1 Wire Info:

http://www.free-cigs.com/Kanthal-A1-Resistance-Wire-AWG-20-22-24-26-28-30-32-33-34–3-Feet_p_155.html

Help With Your PID:

http://www.joppaglass.com/elements/kiln_control/ur_own.html

How to size your element:

http://knifedogs.com/archive/index.php/t-26893.html

http://www.duralite.com/kiln-furnace-studio.htm

http://www.euclids.com/Html%20pages/element-design.htm

http://www.alloyavenue.com/vb/archive/index.php/t-1964.html?s=e1aa591fadbb38282af2bb731828fc04

Total Cost for this project was: $225.41 (even the cheapest used kiln on craigslist I could find was more than this.)